Year after year, exterior remodeling projects prove to offer homeowners the best return on investment, and the Remodeling 2024 Cost vs. Value Report once again affirmed this trend. In fact, the top three projects deliver an ROI as much as twice their cost.

The 37th annual study compares the average costs of 23 remodeling projects with the value those investments will retain at resale. Eight of the top 10 projects delivering the best return were for the home exterior. The top three projects deliver a whopping one-and-a-half to two times their investment: garage door replacement, with 194% cost recovered; steel door replacement, with 188% cost recovered; and manufactured stone veneer, with 153% cost recovered.

Other exterior projects in the top 10 included vinyl siding replacement, (80% ROI) and composite deck addition (68%). The only interior projects in the top 10 were minor kitchen remodel (96%) and mid-range bathroom remodel (74%).

Overall, the remodeling investment return skyrocketed this year. “Compared with last year’s CVV reports, 2024’s has seen a surge in a number of project values, with the average values of the top two projects—the garage door and steel entry door replacements—worth double what they were last year,” the report stated. “These higher values result in ROIs for the top two projects of almost 200%, and an average ROI for the manufactured stone veneer project of over 150%. These ‘hot returns’ are the highest in the history of the Cost vs. Value report and can be attributed to the unique market for existing homes we have in today’s economy with a combination of higher mortgage interest rates and existing homeowners sitting on loads of equity.”

In addition, “a look at yearly trends shows that project costs have increased consistently over the last decade, while perceived values have fluctuated in recent years. This fluctuation has resulted in a fall in the overall ROI as post-pandemic disruptions roiled housing markets,” Remodeling explained. “However, 2024 shows a definitive turnaround with a solid 5.2% increase in averageROI for the 15 CVV projects that have been in the report since its inception in 2002.”

For manufactured stone, the study looked at the cost recouped from replacing a 300-square-foot band of vinyl siding from the bottom third of a home’s street-facing façade with manufactured stone veneer (such as Westlake Royal Building Products’ Versetta Stone, Cultured Stone, and Eldorado Stone) along with sills, corners, and address block as well as a water-resistive barrier. Manufactured stone’s 153% cost recoupment was dramatically higher than last year’s already impressive ROI, increasing 51 percentage points vs. the 2023 study’s 102.3% return.

When the Remodeling 2024 Cost vs. Value report is broken down geographically, manufactured stone shows ROI ranging from 111% to a whopping 220%. In three regions, manufactured stone performed better than the national average: West South Central (Texas, Oklahoma, Arkansas, and Louisiana), with 220% of costs recouped, the most of any category; Pacific (Washington, Oregon, California, Alaska, and Hawaii), with 204%; and Middle Atlantic (New York, New Jersey, and Pennsylvania), with 159%. (See full regional breakdowns here.)

In looking at vinyl siding, Remodeling studied the effect of replacing 1,250 square feet of existing siding with new vinyl siding installed to the manufacturer’s specifications, plus factory trim at all openings and corner and a weather resistive barrier underneath.

Along with an 80% return at the national level, vinyl siding recouped even higher costs in four regions: New England (116% ROI), Mid-Atlantic (96%), Pacific (90%), and West South Central (84%).

Composite decking such as Zuri® Premium Decking also stood out in four regions: Pacific (88% cost recouped), New England (83%), Mid-Atlantic (70%), and West North Central (70%). For these projects, Remodeling evaluated the return on a 16×20-foot deck addition with pressure-treated joists supported by 4×4-inch posts anchored to concrete piers, composite deck material in a simple linear pattern, stairs with three steps to grade, and a built-in bench and planter made of the same decking material.

See the full Remodeling 2024 Cost vs. Value Report study and associated trends at www.costvsvalue.com.

(Remodeling 2024 Cost vs. Value Report: © 2024 Zonda. Complete data from the Remodeling 2022 Cost vs. Value Report can be downloaded free at www.costvsvalue.com.)

6 Fleet Management Software Solutions for Dealers and DistributorsIn an economy where every dollar counts, business efficiency is everything. Fleet management software can help dealers do just that by plotting delivery routes, tracking maintenance, monitoring safety, and more. And thanks to the power of artificial intelligence (AI), offerings are getting more intelligent than ever, helping LBM business owners save time and money.

Here’s a look at some of the options to consider for managing your trucks.

Using GPS, traffic data, and other tools, software programs can help dealers plan delivery routes for efficiency while automatically keeping track of hours and other factors. Many offerings are highly automated, taking the guesswork out of planning and helping you stay on top of delivery deadlines.

Trimble Transportation offers a host of fleet management solutions, including a routing and optimization suite: Trimble Dispatch Advisor, Trimble Trip Alert, and Trimble Expert Fuel. Dispatch Advisor automatically matches drivers to loads based on driver location, delivery windows, hours of service, and more. With Trip Alert, you can monitor hours of service, location, arrival time, and driver appointments to optimize routes as well as understand load balance for planning. Expert Fuel uses real-time data to suggest optimal fuel purchase options for drivers, helping to reduce costs.

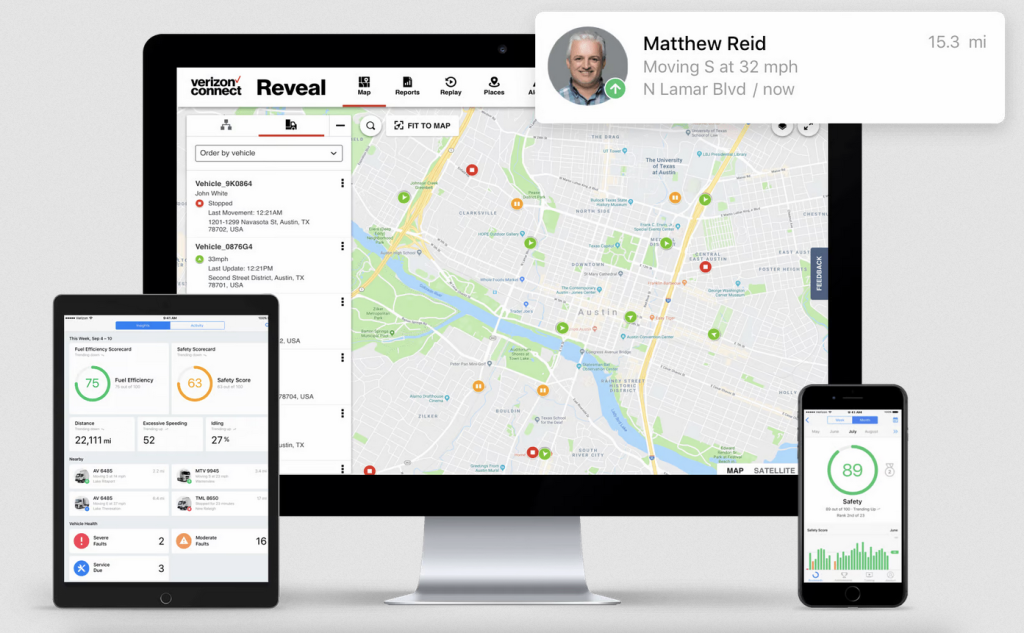

Fleet tracking solutions from Verizon Connect can help distributors improve efficiency by mapping drivers in near-real time, allowing you to keep customers apprised of delivery times, sending alerts upon arriving to or departing delivery locations, and providing turn-by-turn navigation. The software also can monitor driver behaviors and other factors to help improve fuel efficiency as well as track and schedule maintenance.

Safety monitoring is both proactive (encouraging better behavior and alerting drivers to unsafe habits) and reactive (such as providing evidence in the event of an incident), and telematics and AI tools can help. “A telematics tool like a dash camera can detect a number of things, including hard acceleration, driver drowsiness, speed limit violations, following distance, seatbelt compliance, and traffic light and stop sign violations, to name a few,” GPS Insight told Insurance Thought Leadership. “Each second is analyzed for safety via artificial intelligence to recognize risky driving behaviors—and without any human intervention needed.”

TennaCAM 2.0 dash cam from Tenna features dual-facing HD cameras—driver-facing and road-facing—with AI functionality on the interior-facing camera. The camera monitoring and analysis provides managers with data to optimize safety, address risky driving habits, analyze near-misses, and reward better-performing drivers. The cameras pair with the company’s TennaFLEET tracker to provide GPS alerts for hard braking, rapid acceleration, speeding, and other factors as evidence after accidents or other events. The AI technology also can detect risk indicators such as distracted driving, drowsiness, or phone use.

Motive says its new AI Omnicam is the first AI-enabled camera to provide side, rear, passenger, and cargo monitoring; it pairs with the company’s AI Dashcam for 360-degree views of the vehicle, its interior, and its surroundings. Together, the cameras provide insights to help companies resolve issues and streamline operations, including real-time visibility into unsafe or problematic conditions, in-cab coaching and other information to alert and educate drivers, and evidence to exonerate drivers. In the event of an accident, footage uploads in seconds and managers are provided with video and telematics data.

Poorly maintained vehicles can lead to waste—from unexpected downtimes to breakdowns that delay deliveries. Fleet maintenance technology can help track the endless paperwork and schedules while providing automatic alerts for required maintenance so nothing is missed. Some programs also monitor data to help improve fuel efficiency or determine when vehicle replacement is a more economical option.

Fleetio fleet maintenance management software keeps all data about your delivery vehicles—from registration renewal reminders to warranty info to telematics—in one place. It keeps a record of every activity related to each vehicle, including maintenance activities and fuel transactions, while tracking fleet costs and performance. Managers also can manage driver schedules, including assigning trucks and understanding which trucks are being underutilized. An online app allows drivers to view assignments and find vehicle documentation from anywhere.

As part of Teletrac Navman’s TN360 fleet management software, the computerized maintenance management system digitizes vehicle and equipment maintenance schedules, including connecting to each vehicle’s telematics data to track the odometer and engine hours. Managers can build schedules, view a maintenance dashboard across the entire fleet, keep record of all maintenance events, and save important documents, from invoices to certifications. The same platform also can be used to manage vehicle inspections.

Stay up on the latest tools and tips by subscribing to our enewsletter.

8 Hot-Weather Work Gear OptionsMost jobsites don’t come to a halt in the summer heat, which can be uncomfortable—and even dangerous—for workers. Gearing up to keep cool is crucial. From sweat-wicking clothes to jobsite-rugged fans, here are a few hot-weather work gear items to help beat the heat.

Milwaukee Tool’s Cooling PVA Towel activates with water—soak for 30 seconds and wring out—then will wick away moisture and heat for up to four hours. The towel has a UPF 50+ rating to block UV rays. The company also offers similar technology in a safety helmet cooling liner, safety helmet cooling sweat band, hard hat cooling sweat band, and cooling skull cap.

The T1 Werkpant from Truewerk is made with a lightweight softshell fabric for maximum airflow and float yarns for comfort against the skin; a wicking finish on the inside wicks sweat away four times faster than untreated fabric, the company says. The quick-drying pants include eight pockets, a two-button front closure, articulated knees, and double-stitched seams. Six colors are available.

This jobsite fan operates via a plug or on DeWalt’s 20V MAX battery platform to circulate air and cool the area. The fan has variable-speed control, and it can be used freestanding, on hang hooks, wall-mounted, or tripod-mounted.

The Chill-Its hydration pack from Ergodyne holds 2 liters of water while offering a low profile that’s comfortable for all-day wear. The durable pack is made with rugged 600D ripstop polyester and features an antimicrobial bite valve with cover, wide opening for easy filling, insulation to keep the water cool, and a breakaway design for safe detachment. Three color options include high-vis orange and high-vis lime as well as black.

Carhartt’s Force Sun Defender relaxed fit, lightweight short-sleeve button-down shirt features UPF 50+ UV protection along with Fast Dry technology that wicks away sweat and dries fast. Other features include Rugged Flex stretch technology, Carhartt Force odor-fighting technology, back vent and underarm eyelets, a spread collar, and button-closure front pocket. It comes in Steel and Dew Drop colors.

The Armachillo Relaxed Fit Pocket Crew T-Shirt from Duluth Trading Company features microscopic jade in the fabric, which produces a cooling sensation that the company says lowers skin temperature, and its polyester/nylon knit wicks moisture and dries quickly. It also has an odor-fighting finish. The shirt has a longer length, and it comes in five colors.

The PIP EZ-Cool vest from PK Safety is made with HyperKewl, an evaporative material that absorbs and slowly releases water to create a cooling effect for five to 10 hours, cooling the body by 15 to 20 degrees, the company says. The hot-weather work gear vest has a V-neck design and zipper closure. Six sizes are available.

When activated, the Cooling Helmet Liner from Klein Tools cools up to 30 degrees below body temperature while wicking sweat away from the head. It has mesh fabric at the crown for breathability and airflow. The liner is machine washable.

Want more cool finds? Subscribe to our enewsletter here.

Celebrate National Home Remodeling Month With Resources and ToolsMay brings sunny skies and warmer temps—and the NAHB’s National Home Remodeling Month. This annual celebration recognizes remodelers and the remodeling industry with resource, tools, spotlights, and discussions. Westlake Royal Building Products™ is proud to sponsor this important event for the third consecutive year.

Throughout the month, remodelers can access an exclusive tool kit with marketing tools and social media templates to craft top-notch local media campaigns along with the latest industry news to help you stay ahead of market trends. NAHB also will be hosting two Shop Talk discussions May 9 and May 23 and a webinar on May 18. These sessions will include conversations with industry experts aimed at assisting professionals in developing strategic marketing plans for their remodeling businesses in addition to helping them understand how leveraging social media can expand a company’s reach.

And be sure to follow along on social media, using the hashtag #NAHBRemodelers, to share your own insights and read commentary and tips from peers and other experts.

Westlake Royal Building Products™ is the title sponsor of National Home Remodeling Month.

“We’re excited to continue our support of the remodeling industry by sponsoring this initiative for the third year in a row. Remodeling is more than just a project; it’s a pathway to happiness for homeowners looking to transform their living spaces without the stress of moving. It’s about creating more room for cherished memories, enhancing energy efficiency for a greener future and ultimately, increasing the value of one’s home,” said Steve Booz, vice president, marketing & product management at Westlake Royal Building Products. “We’re thrilled to be part of this journey and to support NAHB’s members in their dedication to excellence and customer satisfaction.”

To get started and access tools and events, visit NAHB’s National Home Remodeling Month landing page.

Stay up on industry events and resources by subscribing to our enewsletter here.

What Home Buyers Want the MostWhat features are most in demand from new-home buyers? NAHB sought the answers in its latest “What Home Buyers Want” report. Among the top and/or fastest-growing in-demand features were laundry rooms, patios, and home security.

In the What Home Buyers Want study, buyers were given a list of more than 200 home and community features and asked to rate them as “essential,” “desirable,” “indifferent,” or “do not want.”

According to Eye on Housing, of all the features in the study, there were 13 that ranked “essential” by at least 80% of respondents:

In addition, there were a handful of features that made tremendous gains in popularity over the past decade. All were in the area of technology, including security cameras (climbing 36 percentage points in 12 years), wired home security systems (35 percentage points), and programmable thermostats (31 percentage points).

When it comes to exterior design styles, Eye on Housing found no national consensus in the study. “At best, a plurality of 34% would prefer to purchase a ‘traditional’ home (rooted in historic styles), while a smaller 26% would rather buy a ‘contemporary’ home (clean lines, sloped roofs, expansive windows),” Rose Quint reported. “Far smaller shares of 17% and 12% of buyers, respectively, would choose a ‘modern’ home (bold, boxy, flat roofs) or a ‘transitional’ home (contemporary design with traditional cues).

Delving further into in-demand exterior features, consider the results of AIA’s quarterly Home Design Trends survey. In its Q4 2023 edition, examining Neighborhood and Community Design, the survey reported that “low maintenance/durability” continue to be the most popular feature, with 59% of architects reporting increasing interest. Unlike the NAHB study, the AIA survey found contemporary styling to be most common, with 51% of architects reporting increasing interest, down just 1 percentage point from 2022.

To learn more about what’s in demand, the full “What Homebuyers Want” report is available for purchase here.

Stay up on all the latest trends and industry insights by subscribing to our enewsletter.